Robosport Axon Batting Tee

Robosport Technologies set out to disrupt traditional baseball training tools with a robotic batting tee that autonomously adjusts to multiple pitch positions within the strike zone. They needed a partner to make the concept real — and SPEED was that partner, leading every step of the development journey.

The Challenge:

Create an automated tee system that can randomly adjust tee height and position after each swing.

Integrate ball detection and swing detection to trigger repositioning.

Ensure the solution is durable, safe, and manufacturable for repeated use in athletic training environments.

Deliver cross-disciplinary integration: mechanical actuation, embedded electronics, sensors, firmware, and user-ready hardware.

Maintain budget and timeline constraints while bringing an entirely new product category to life.

-

Feasibility Study

The feasibility phase of the RoboSport training tee project focused on evaluating mechanical solutions for vertical (Z-axis) movement. Several actuator types were analyzed for stroke length, compactness, cost, and reliability. Many were ruled out due to size, cost, or performance concerns. The Flex Screw Drive and Cable + Strut systems emerged as the most viable. A preferred solution was chosen for its compact design, affordability, and radar compatibility—establishing a strong foundation for product development.

-

Industrial Design

The industrial design phase of the RoboSport tee project focused on form development aligned with user preferences and technical constraints. A minimalist aesthetic was favored, avoiding vintage or overly organic styles. Multiple enclosure concepts were explored, balancing internal component fit with usability and ergonomic handling. Key refinements included repositioning the handle vertically, angling the display toward the batter, and embedding components to optimize portability and footprint. The final concept advanced these preferences, integrating branding elements, refining dimensions, and enhancing both form and function to support further development.

-

Mechanical Engineering

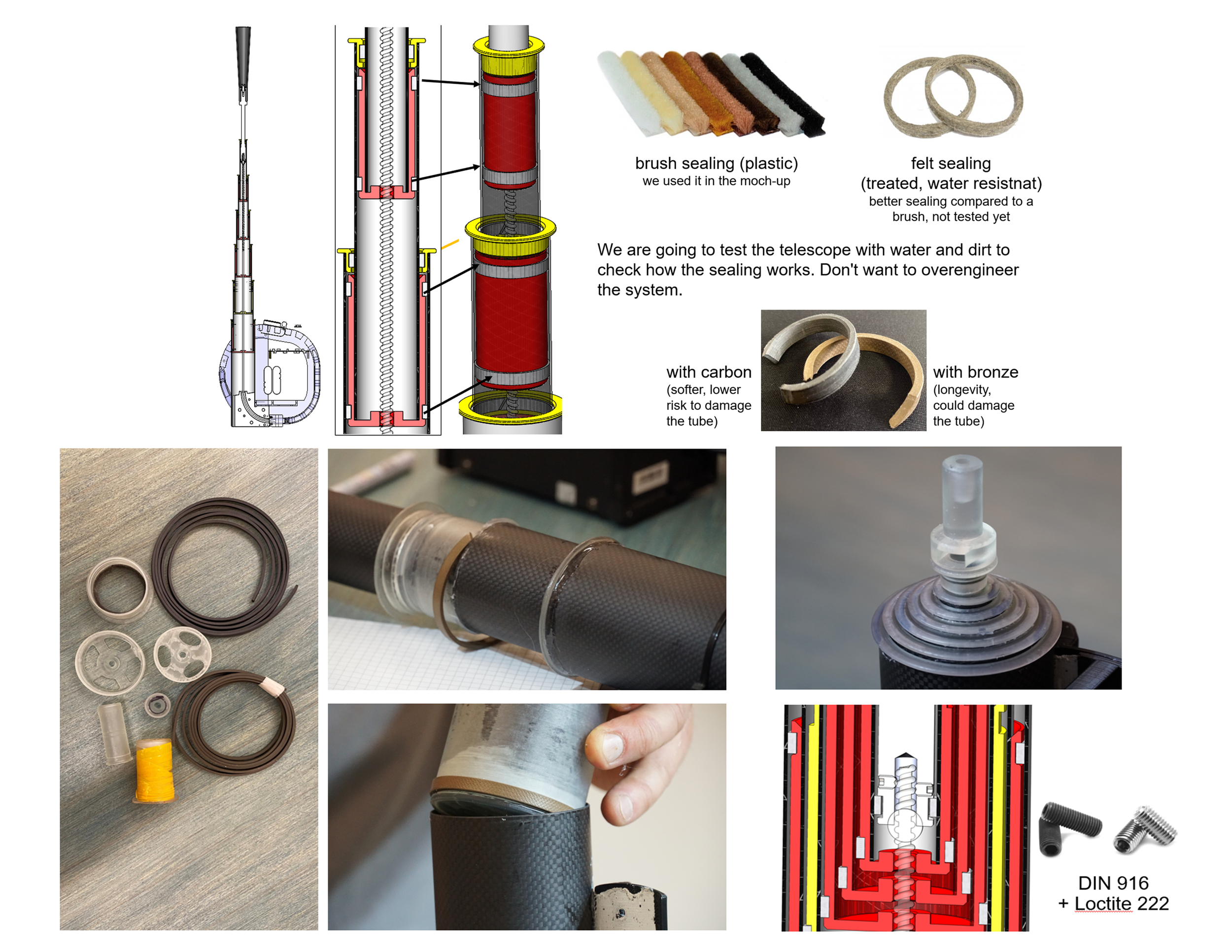

The mechanical engineering team focused on developing and refining the telescopic actuation system for the RoboSport tee. Two design options were evaluated, with a preference for the version offering fewer sealing types and reduced surface friction—resulting in lower production costs and better long-term durability. A physical prototype was built to test actuator performance, leading to successful validation of the LAF 2 A 1/12 actuator. Design refinements, including adjustments to the flexible screw path and coil geometry, reduced power consumption by 25%. Additionally, updates to the rail unit design led to a 20% power efficiency gain. Assembly methods and sealing strategies were also tested to balance performance and manufacturability without overengineering the system. Acheived product requirement of 610K cycles.

-

Electronics & Firmware

Electronics development began with assembling a mock-up to support actuator testing. A motor driver was tested and performed reliably without overheating. Firmware was created to enable manual motor control via pushbuttons and support telescope system testing. Core components—including an MCU, radar, accelerometer, and NFC module—were integrated into a compact layout within the enclosure. Ongoing work included finalizing the 3D model placement, developing motor encoder interaction, launching the NFC module, and completing the electrical layout. Power optimization was also achieved, with the system operating well below the motor’s nominal current rating of 2A, consuming just 420–460 mA in its current configuration.

-

Prototyping

The prototyping phase of the RoboSport training tee project focused on integrating and validating key mechanical, electronic, and user interface components in a functional, testable unit. The physical prototype featured a fully telescoping vertical column, confirming the mechanical feasibility of the flexible screw drive mechanism and achieving the required height range for ball placement. A swappable battery system was successfully integrated for power portability and ease of field use. The enclosure, fabricated via 3D printing, housed the core electronics including an LCD display, tactile buttons, LED indicators, and an RFID/NFC target zone—demonstrating user interaction, system status visibility, and smart device readiness. This prototype served as a critical step in evaluating real-world performance, refining usability, and preparing for certification and manufacturing.

-

Design For Manufacturing

The Design for Manufacturing phase focused on refining the product architecture to enable cost-effective, scalable production. Key tasks included optimizing component layouts, finalizing material selections, and simplifying part geometries to align with injection molding, CNC fabrication, and standard assembly processes. The team consolidated mechanical and electronic assemblies to minimize part count, improve durability, and streamline the build sequence. A complete documentation package—BOM, 2D/3D CAD, assembly views, and manufacturing drawings—was created to support vendor engagement. Thermal and mechanical tolerances were validated to meet operational demands, while supply chain considerations helped ensure reliable sourcing of key components.